Linear actuators go a long way to ensure the safety of valuable machines and also known to take active part in enhancing the performance and productivity in industries. And with the flourishing of industrial units, the concept has been gaining more popularity all over. Thus, modern manufacturers come with a range of motion controllers which are ideal for use in various industry sectors.

In this article, we will throw light on types and application areas of linear motion controllers.

Types

Among a number of useful devices used in industries, an important device is linear actuator. As the device is known to come equipped with a linear motor, it helps in preventing in linear motion of the machine due to vibration that occurs during operation. Adding to it, the rotary motion gets converted to linear motion with the help of this device. In short, it promotes safer machine operation.

Actuators are classified into different types as per the nature of their power feature. Some are designed to get powered by electricity, some by hydraulics and pneumatics. Whatever be the type, the motive of the device is to convert the rotary motion into the linear.

And the selection of type of actuators is dependent on your area of application as well as the budget to own the devices. If we talk about industrial users, they usually make use of electric motion controllers as the source of power required is clean, simple and energy-efficient power transmission.

Application Areas

As discussed earlier about the performance and work ability of devices, actuators can be used in industrial sectors where it is required to mobilize payloads in a straight line by making use of thrust force. It should be noted that the application of such devices can be found in simple device like car jack to big machinery like bulldozer, etc. And certain factors are there which are considered by companies during manufacturing. Such factors include stroke length, load rating, speed and lots more.

If we talk about application areas, the electric actuators are getting used in agricultural, mining, construction, etc. Certain industrial equipment can also be found where the application can be noticed like to control seats, doors, hoods, covers, throttles and many others.

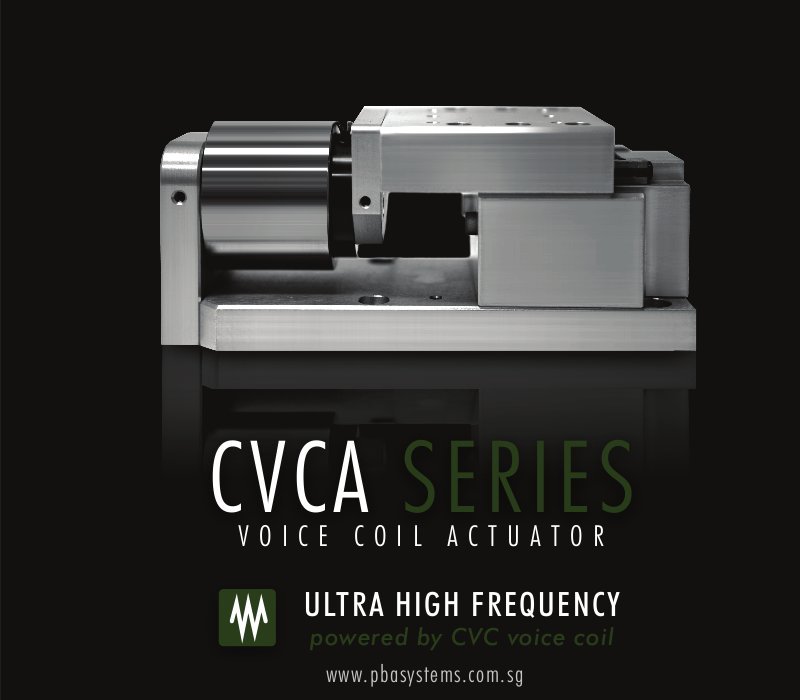

PBA Systems, an ISO 9001: 2008 Cert No. 601191 certified company, designs and manufactures motion control products, including linear motor modules, voice coil modules, piezo stages, large XYZ Theta stages and other special customized solutions.

PBA Systems Pte Ltd

505 Yishun Industrial Park A

PBA Building

Singapore 768733

Tel : +(65) 6576 6767

General Enquiry / Sales: [email protected]

Website : www.pbasystems.com.sg

RSS Feed

RSS Feed